Meat and poultry as well seafood and juice companies are required to implement an HACCP plan.

Is HACCP a voluntary process?

In the United States, the Food and Drug Administration requires juice, seafood, and meat and poultry companies to utilize an HACCP plan. While adhering to the HACCP process is not mandatory for all food businesses, following the HACCP guidelines is commonly recommended by food inspectors.

What is HACCP?

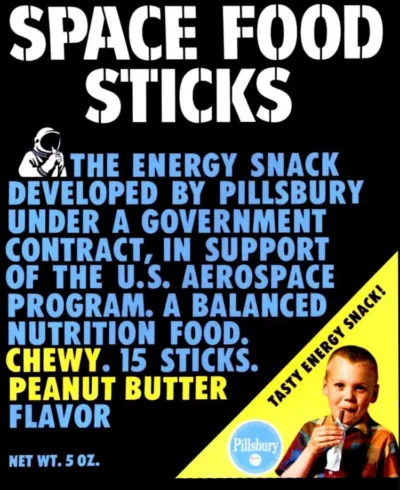

HACCP stands for Hazard Analysis and Critical Control Point and is a standardized, internationally recognized system to prevent or reduce food safety hazards in food manufacturing. In the US, HACCP is administered by the Food Safety Inspection Service (FSIS) which operates under the FDA. Established in the 1960s by a partnership of NASA, US Army Labs, and the Pillsbury Company, it was originally designed to put together standards for creating food that would be safe for astronauts in space.

The reduction of the number of pathogenic microorganisms can reduce the incidence of food-borne illness. Some of these food-borne hazards are listeria monocytogenes, salmonella, shigella, and others.

The set of procedures for implementing HACCP is a “whole food chain” approach to eliminating threats before they occur. From production to packing and distribution, the idea behind the HACCP is to provide integrity in food manufacturing with a clear set of best practices that protect consumers. Regardless of whether a company is required to implement HACCP, numerous food and beverage manufacturers implement controls based on the HACCP standard. As a result, many internal company manuals are written to specifically target food safety, and these are often accompanied by rigorous internal training and audits.

The Seven HACCP Principles

Conduct a Hazard Analysis

Determine Critical Control Points

Establish Critical Limits

Establish Monitoring Procedures

Establish Corrective Actions

Establish Record-keeping Procedures

Establish Verification Procedures

- Principle 1 – Hazard Analysis includes identifying all types of pathogens, toxins, and contaminants that could possibly enter your food production process. This includes an analysis of hygiene and microbes.

- Principle 2 – Critical Control Points help identify at which point or step a hazard can be eliminated or controlled. For example, if there is a fermentation process in your manufacturing, what specifically needs to be monitored? Is it the time, the PH, or other things?

- Principle 3 – Critical Limits establish the minimum requirements for the Critical Control Points.

- Principles 4 & 5 Monitoring Procedures and Corrective Actions provide the follow-through required to ensure integrity and complete the HACCP process.

- Principles 6 & 7 Record-keeping and Verification Procedures provide the tracking for what was done as well as future plans to manage food safety.

Automation can do more than increase efficiency, it can help you increase the safety and quality of your food and all of the ingredients in the food manufacturing process. SimplyFood software can assist with compliance and traceability requirements by having a way to input data and notes every step of the way.